Presented originally at the 2025 ARA Conference and Expo in Salt Lake City — expanded here in blog form.

On Tuesday, I joined two fellow panelists to share how technology can improve operational efficiency. My portion focused on a simple but persistent challenge nearly every retailer faces: operational blind spots.

Across our plants and logistics, we depend on assets like trailers and bulk material that move constantly. Not knowing when trailers are empty, where they are located, or what's going on with our physical inventory in between monthly manual estimates have been some pretty big blind spots.

Over the last three years, we’ve invested heavily in eliminating those blind spots which has dramatically improved operations. This leads directly to improved customer service.

Here are three examples from my talk which preceded a very engaging Q&A session with the panel.

Case Study #1 — Liquid Trailers

Knowing Exactly What’s Full, Empty, and Where Everything Is

Problem

We operate a lot of liquid fertilizer trailers across Florida. At peak times we'd run low on trailers, creating a lot of pressure to meet customer expectations on delivery times. Dispatch and sales teams would spend valuable time calling around trying to find empties we could pick up.

It's of paramount importance for us to be able to not only meet but to exceed our customer expectations. We had to find a solution and fast.

The root problem: no visibility into fill levels.

Solution

We found an off the shelf solution. TankScan sold IoT sensors with a backend that provided an API for integrating the data into our systems. These sensors will read fill levels of the tank periodically and then send that data long with GPS coordinates to their servers over cellular networks.

We ran a test on a few trailers. Determined it worked and we could fetch the data from their API. Then rolled out on rest of the fleet within months.

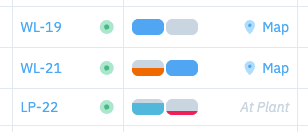

We pull this data into our system so we can tailor alerts and display in a dispatch dashboard.

Outcome

Now we can no only see what trailers are empty but we can see precise fill levels of each tank on a trailer.

In addition, we have:

- No more wasted trips

- No more running out of trailers

- Data-driven dispatching

The best part is how quickly this one change improved team coordination. We are making decisions on pickups based on data rather than intuition.

Case Study #2 — Dry Trailers

When No Vendor Exists, Build the Tool You Need

Problem

Our Killebrew trailer fleet presented the same visibility problem but this time, there was no off-the-shelf solution.

Killebrew trailers are more than just a trailer. They have a small engine with controls that lift each of the four bins up and to the side via hydraulic arms. The bins tilt to empty material into a spreader that is pulled up next to the trailer.

Nothing existed to tell us whether a bin had been emptied.

So we built it.

Solution

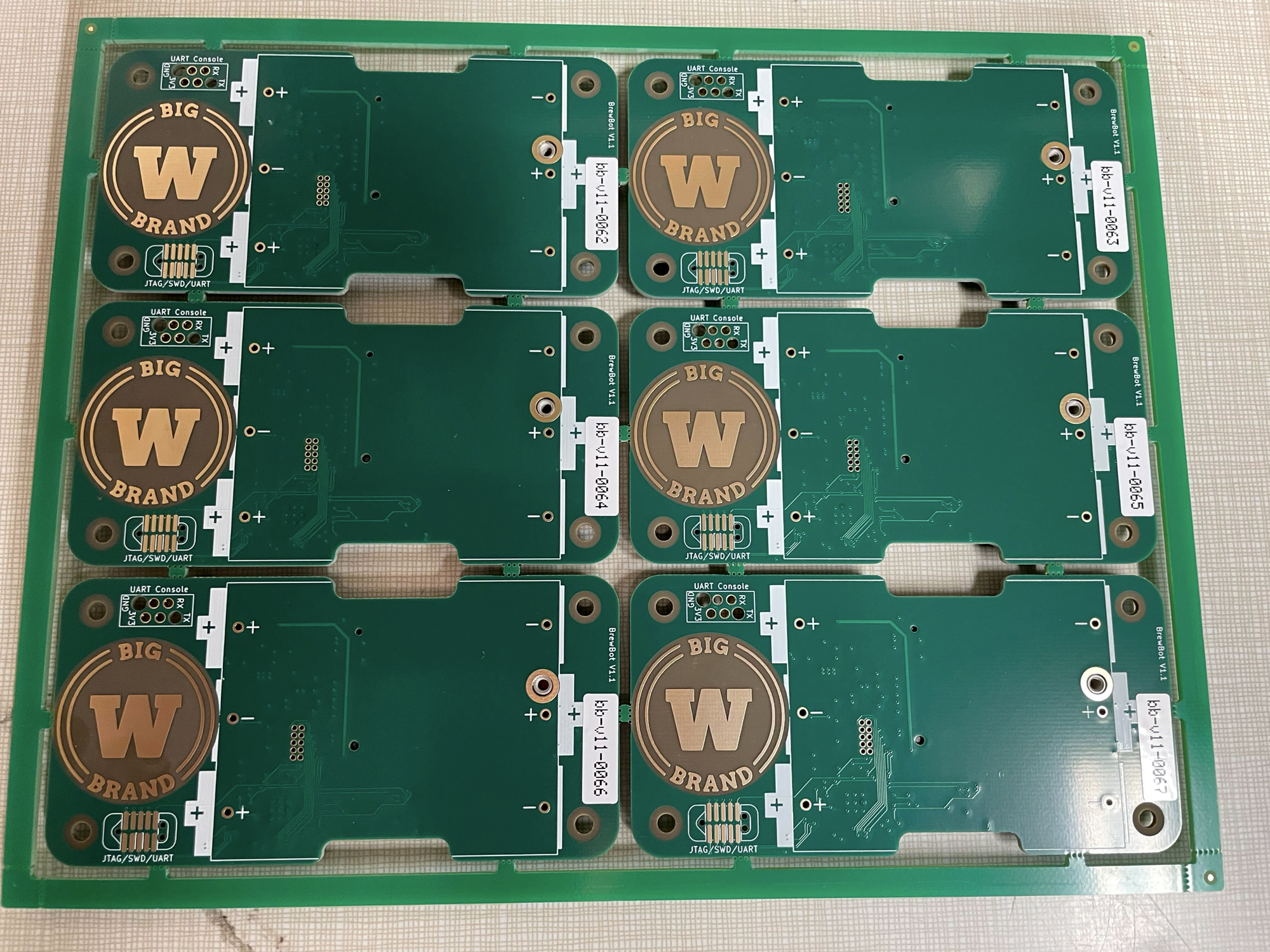

We created a custom IoT device that detects tilt angle. On these trailers, a tilt high enough and for long enough, reliably means “this bin has been emptied,” so we built around that signal.

The path we took looked like this:

- In-house prototype

- Partnering with an engineering firm - (Geocene has been a great partner to bring this to life)

- Proof of concept

- Field testing

- Production hardware

Each device combines an accelerometer, microcontroller, and cellular modem — rugged, low-power, and built specifically for these trailers.

Outcome

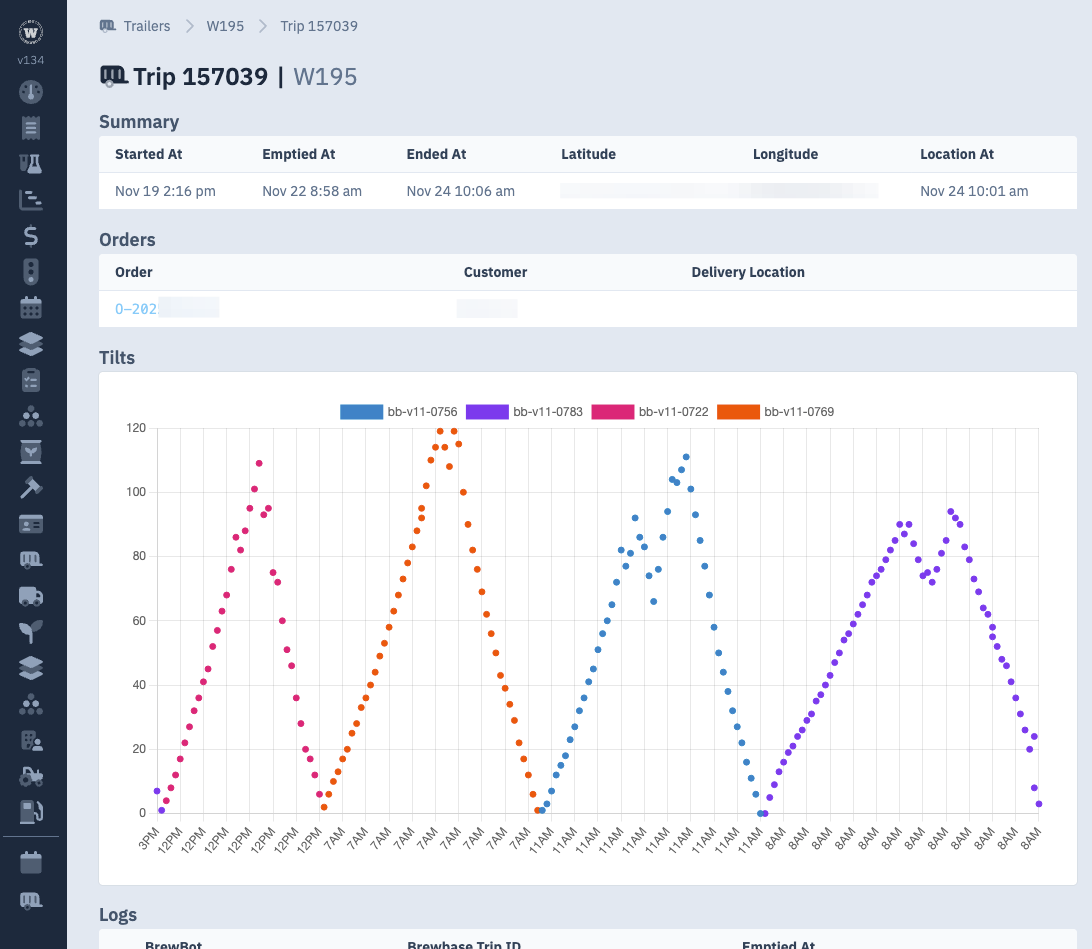

Now we can see every movement of each bin on every trailer.

- Fleet-wide visibility into trailer empties

- Major relief during peak times when trailer shortages would bottleneck operations

- A meaningful competitive advantage in asset efficiency

And perhaps most importantly, it proved to our team that we can build whatever we need.

Case Study #3 — Bulk Pile Inventory

Real-Time Physical Inventory at Scale

Problem

Across our four plants, we maintain over sixty bulk material piles and move more than a quarter-million tons annually. Historically, pile measurement was manual, and labor-intensive. Because of this, we'd only take a physical inventory on a monthly basis. The manual measurements could have a ±8% variance, maybe more depending on size of the pile.

Solution

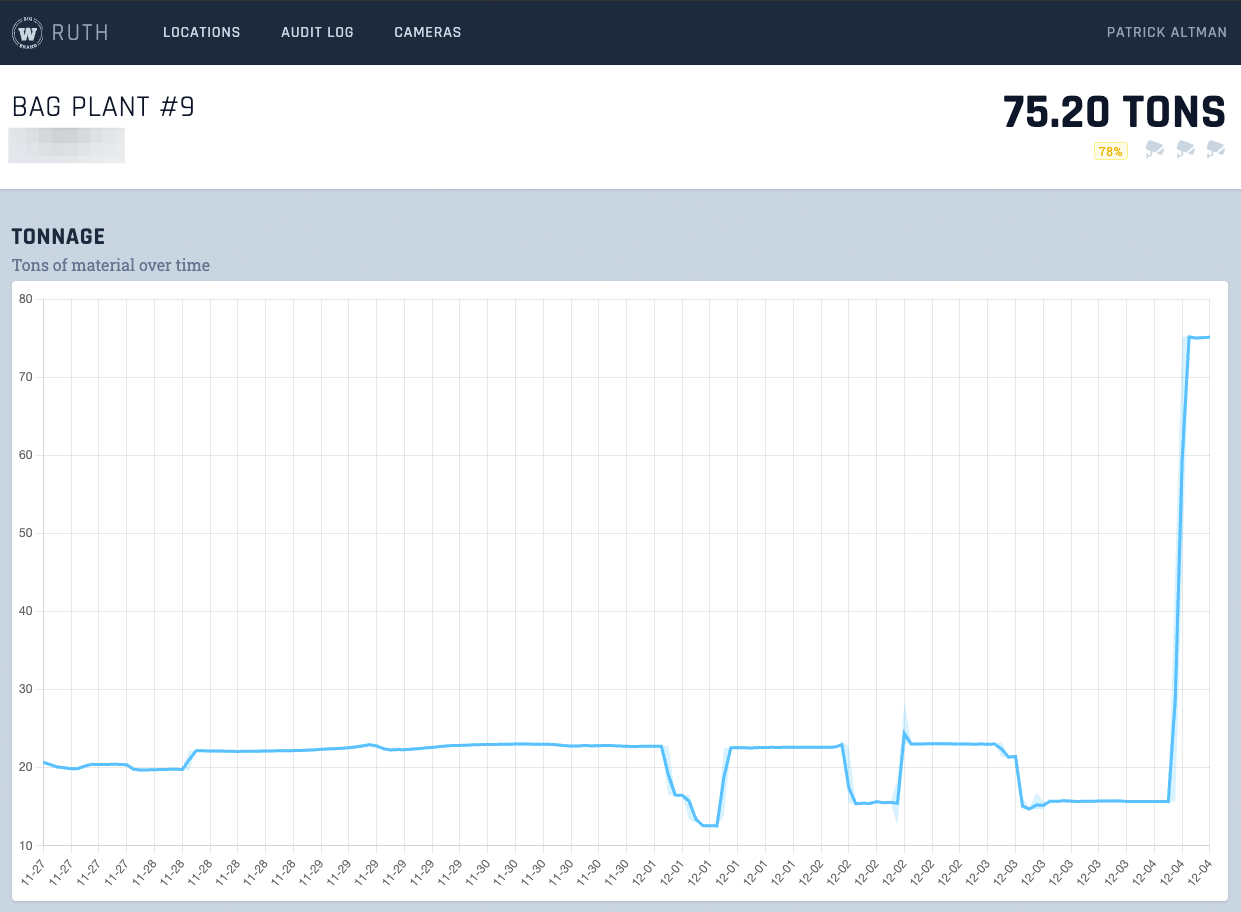

We deployed LiDAR cameras from Blickfeld (another great technology partner who I can't say enough great things about) that continuously scan each pile and calculate volume in real time. The software driving these cameras provides a data feed of these real-time volume estimates.

We built a web application around this vendor solution to handle:

- material management,

- bulk density measurement captures,

- inventory visualization and more.

The application consumes the volume estimate feed from Blickfeld's software to give us live tonnage.

Outcome

- Eliminates manual measurement labor

- Real-time visibility instead of 30-day snapshots

- Accuracy tightens dramatically (±8% → 0.6%)

- A stable, trustworthy baseline for managing COGS and shrink

This project has fundamentally changed how we think about inventory, costing, and operational planning.

What These Projects Have in Common

Across these three examples, a few themes emerged:

- We created data where none existed.

Sensors and automation enabled us to see more. - Immediate operation impacts.

Each project paid off quickly because inefficiencies were real and recurring. - Culture changed.

Once folks get used to real-time data, expectations shift–standards rise.

What’s Next

This post captures the high-level version of what I shared at ARA. Over the coming months, I plan to publish deeper technical pieces on how we built these systems — from designing custom IoT hardware to integrating live data streams into a custom ERP.

If you were part of the ARA session, thanks again for the great conversation. If you weren’t, I hope this post gives you a sense of what’s possible when you make the right technology investments into operations.

Thanks to Brian Blodgett (Next Generation Technologies) for moderating and to my co-panelists, Joshua Ussel (Willard Ag) and Garrett Asmus (Asmus Farm Supply). These are three great guys that are worth getting to know.